Introduction

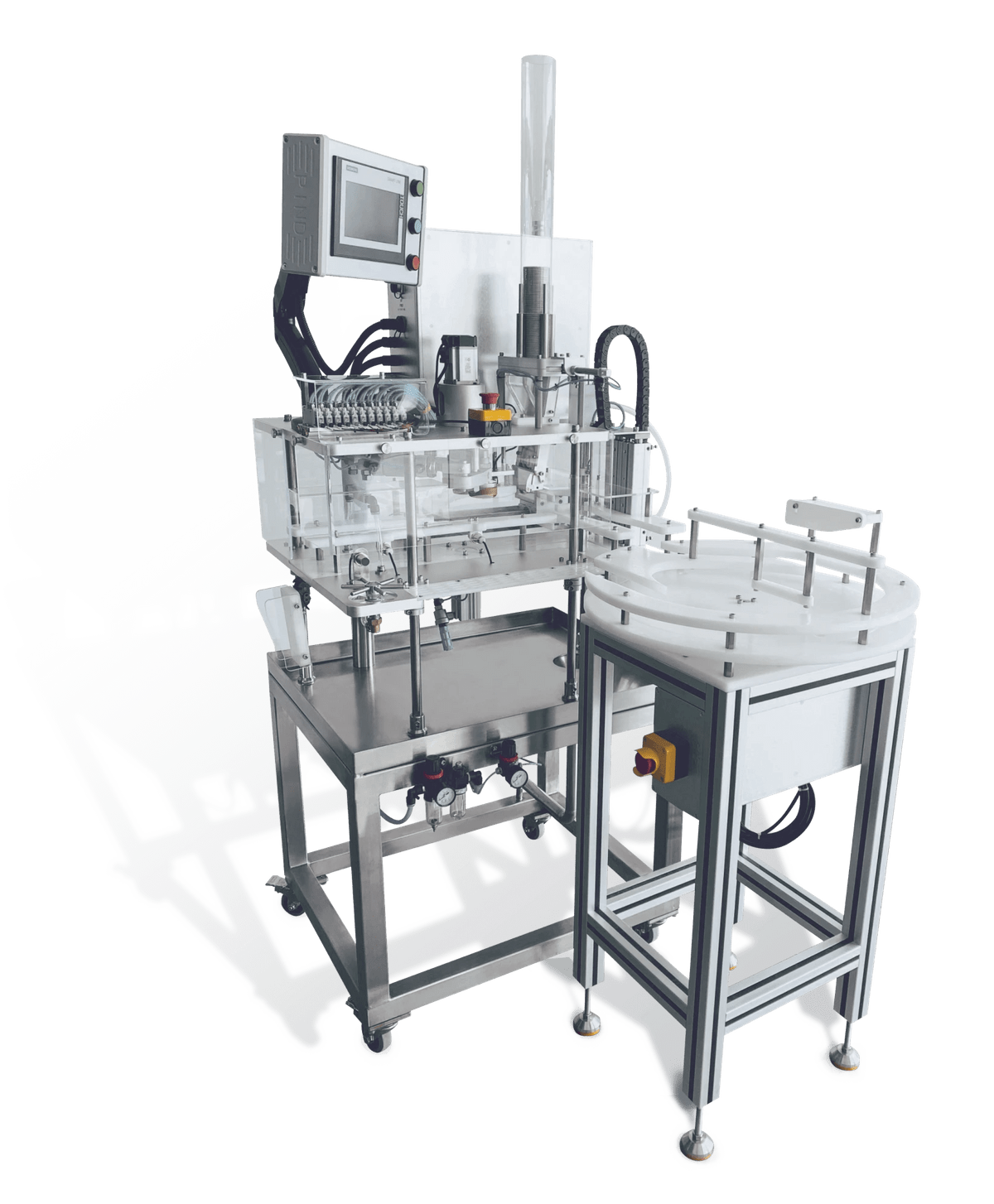

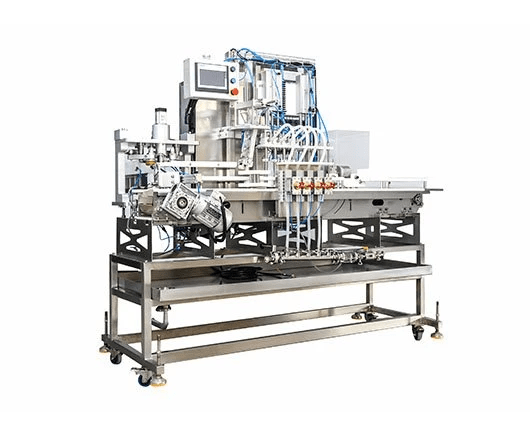

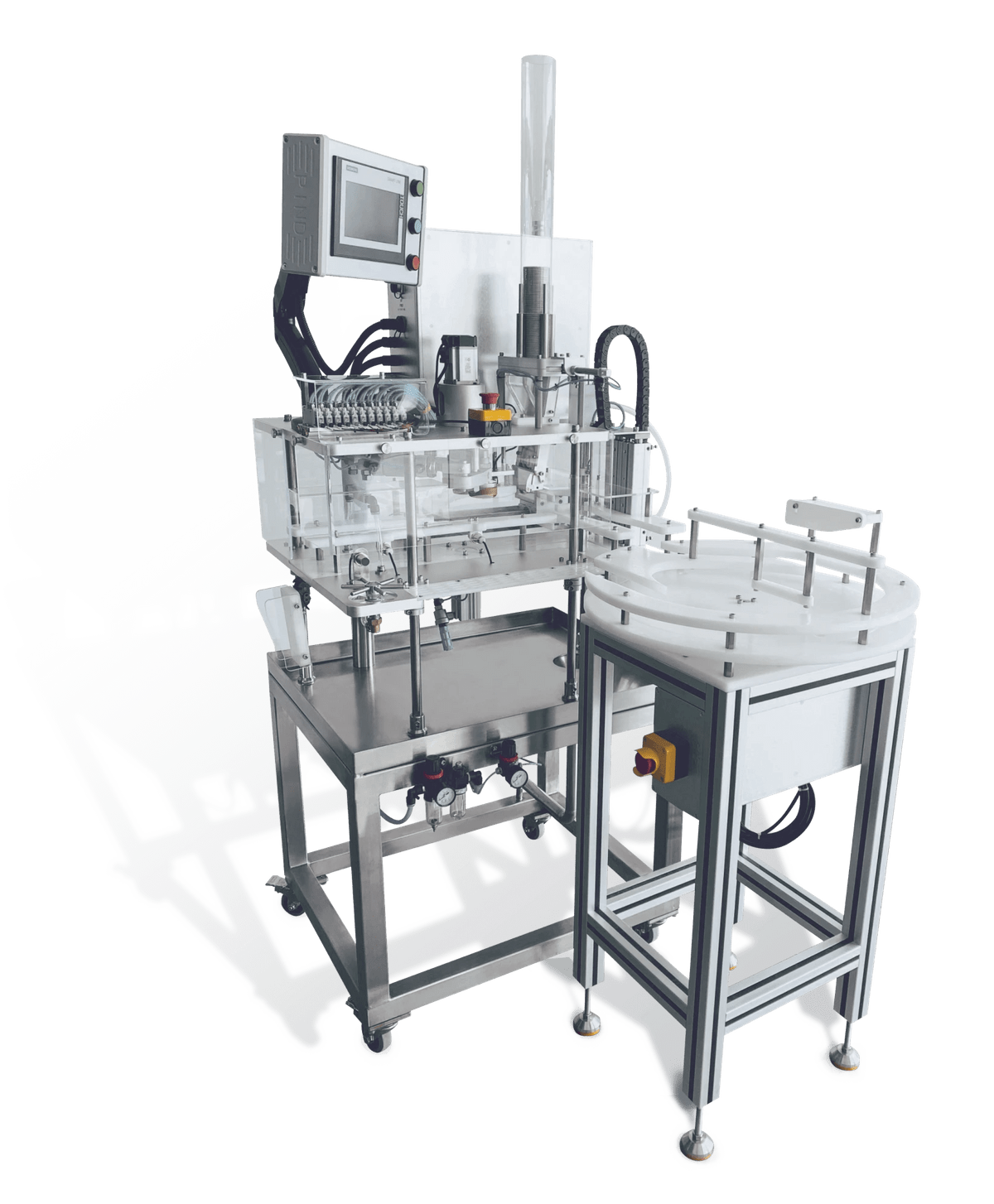

Beer can filling machines play a crucial role in the brewing industry, ensuring efficient production and high-quality products. Automatic beer can filling machines, in particular, have revolutionized the way breweries operate by improving productivity and reducing labor costs. Trano Keg Company, a trusted provider of quality machinery, has introduced the streamlined automatic beer can filling machine to meet the specific needs of breweries. In this article, we will explore the importance of efficient beer can filling machines, how automatic machines improve production, the role of Trano Keg Company in the brewing industry, and introduce their innovative automatic beer can filling machine.

The Importance of Efficient Beer Can Filling Machines

Efficient beer can filling machines are essential for breweries to meet the demands of consumers and maintain profitability. These machines ensure that each can is filled accurately and quickly, reducing product waste and increasing production efficiency. By utilizing advanced technology and precise mechanisms, these machines streamline the entire filling process while maintaining consistent quality.

How Automatic Beer Can Filling Machines Improve Production

Automatic beer can filling machines have revolutionized production processes in breweries by automating repetitive tasks and minimizing human error. With high-speed filling capabilities, these machines significantly increase productivity by efficiently handling large volumes of cans within a short period. They also offer precision filling to avoid product waste and ensure every customer receives a properly filled can.

The Role of Trano Keg Company in Brewing Industry

Trano Keg Company is a renowned designer and exporter of stainless steel beer kegs with an international reputation for excellence in the brewing industry. They understand the unique challenges faced by breweries when it comes to efficient packaging solutions. With their expertise in designing top-of-the-line machinery, Trano Keg Company has become a trusted partner for breweries worldwide.

Features of Automatic Beer Can Filling Machine

The automatic beer can filling machine offers a range of features that enhance the efficiency and productivity of breweries. Let's explore these features in detail.

High Speed Filling for Increased Productivity

The beer can filling machine is designed to operate at high speeds, ensuring increased productivity for breweries. With its advanced technology, it can fill a large number of cans within a short period of time. This feature allows breweries to meet the demands of their customers and maximize their production output.

Precision Filling to Avoid Product Waste

Precision filling is another key feature of the automatic beer can filling machine. It ensures that each can is filled with the exact amount of beer, avoiding any product waste or inconsistencies in quality. This precise filling process guarantees customer satisfaction by delivering consistently filled cans with the perfect amount of beverage.

User-Friendly Interface for Easy Operation

The user-friendly interface of the beer can filling machine makes it easy for brewery operators to operate and control the machine effortlessly. The intuitive design and clear instructions enable seamless operation, reducing the chances of errors or accidents during the filling process. This user-friendly feature enhances overall efficiency and saves valuable time for brewery staff.

Customizable Settings to Meet Brewery's Specific Needs

Every brewery has unique requirements when it comes to beer can filling. The automatic beer can filling machine offers customizable settings that can be adjusted according to each brewery's specific needs. Whether it's adjusting fill levels, controlling carbonation, or accommodating different can sizes, this flexibility ensures optimal performance tailored to individual brewing processes.

Benefits of Using Automatic Beer Can Filling Machine

The adoption of automatic beer can filling machines brings numerous benefits to breweries, enhancing efficiency and reducing labor costs. These machines ensure consistent filling quality, minimizing product waste and maximizing customer satisfaction. Additionally, they offer minimal downtime, increasing production output and meeting the demands of a growing market. Moreover, automatic beer can filling machines are compatible with various can sizes and beverage types, providing flexibility for breweries to diversify their offerings.

Enhanced Efficiency and Reduced Labor Costs

Automatic beer can filling machines revolutionize the production process by streamlining operations and reducing the need for manual labor. With high-speed filling capabilities, these machines significantly increase productivity, allowing breweries to meet higher demand while optimizing their resources. By automating the filling process, breweries can allocate their workforce to other essential tasks, ultimately reducing labor costs.

Consistent Filling Quality for Customer Satisfaction

Maintaining consistent product quality is crucial for customer satisfaction in the brewing industry. Automatic beer can filling machines ensure precise and accurate filling levels every time, eliminating variations that may occur with manual operations. This consistency enhances the overall drinking experience for consumers by delivering a reliable product that meets their expectations consistently.

Minimal Downtime and Increased Production Output

Downtime in production can be costly for breweries as it disrupts workflow and delays order fulfillment. Automatic beer can filling machines are designed to minimize downtime through efficient operation and quick changeover between different beverage types or can sizes. This feature allows breweries to maintain a steady production flow without unnecessary interruptions or delays.

Trano Keg Company: A Trusted Provider of Quality Machinery

Commitment to Delivering Reliable Brewing Equipment

Trano Keg Company is committed to providing breweries with reliable brewing equipment, including their automatic beer can filling machines. As a trusted provider in the industry, Trano understands that downtime can be costly for breweries, affecting production schedules and customer satisfaction.

To ensure reliability, Trano conducts rigorous quality control tests on all their machinery before delivery. Each automatic beer can filling machine undergoes comprehensive performance checks to guarantee its functionality and efficiency. By prioritizing reliability, Trano enables breweries to streamline their operations without worrying about equipment malfunctions or interruptions in production.

International Reputation for Superior Customer Support

One aspect that sets Trano apart from other beer can filling machine manufacturers is their exceptional customer support. With an international reputation for providing superior service, Trano goes above and beyond to assist breweries throughout the entire purchasing process.

From initial inquiries to after-sales support, Trano's dedicated team is always available to address any concerns or questions that arise. Their prompt responsiveness ensures a smooth and hassle-free experience for breweries seeking efficient beer can filling machines. Trano's commitment to customer satisfaction extends beyond the sale, as they continue to provide support and guidance long after the machinery is installed.

Installation and Maintenance of Automatic Beer Can Filling Machine

Installing and maintaining an automatic beer can filling machine is essential for ensuring seamless integration into your brewery's production line. Trano Keg Company, a trusted provider of quality machinery, offers professional installation assistance to guarantee a smooth setup process.

Professional Installation Assistance for Seamless Integration

Trano Keg Company understands the importance of proper installation to maximize the efficiency of your beer can filling machine. Their team of experts will guide you through the entire installation process, ensuring that the machine seamlessly integrates into your existing production line.

During installation, Trano's technicians will carefully connect all necessary components and calibrate the machine for optimal performance. They will also provide training on how to operate and maintain the equipment effectively.

Routine Maintenance Guidelines for Longevity and Performance

To ensure longevity and consistent performance of your automatic beer can filling machine, following routine maintenance guidelines is crucial. Trano Keg Company provides comprehensive maintenance instructions to help you keep your equipment in top condition.

Regular cleaning is essential to prevent any residue buildup that could affect the efficiency of the filling process. Trano recommends using approved cleaning agents and following their guidelines for proper cleaning procedures.

Additionally, routine inspections should be conducted to identify any signs of wear or damage that may require immediate attention. Regular lubrication of moving parts is also recommended to minimize friction and maintain smooth operation.

Access to Trano's Technical Support for Prompt Assistance

Trano Keg Company values customer satisfaction and provides prompt technical support for any queries or concerns regarding their automatic beer can filling machines. Their dedicated team of experts is readily available to assist you in resolving any issues that may arise during operation.

Whether you need clarification on maintenance procedures, guidance on troubleshooting, or assistance with spare parts replacement, Trano's technical support team will ensure that your concerns are addressed promptly and effectively.

By choosing Trano as your supplier of automatic beer can filling machines, you gain access not only to superior machinery but also reliable technical support throughout your brewing journey.

With professional installation assistance, routine maintenance guidelines, troubleshooting tips, and access to prompt technical support from Trano Keg Company, you can rest assured that your automatic beer can filling machine will operate optimally while contributing to the overall efficiency of your brewery's production line.

Remember, embracing automated solutions like the ones offered by Trano elevates your brewery's production capabilities and keeps you ahead of the competition in the dynamic brewing industry.

Cost-effectiveness and Return on Investment

Beer can filling machines are a valuable investment for breweries, offering cost-effectiveness and a quick return on investment. With their ability to increase efficiency and streamline operations, these machines provide numerous benefits that positively impact overall brewing business profitability.

Reduced Production Costs through Increased Efficiency

One of the key advantages of using a beer can filling machine is the significant reduction in production costs. These machines are designed to operate at high speeds, allowing for increased productivity and faster turnaround times. By automating the filling process, breweries can minimize labor requirements and optimize their resources more effectively.

With a tabletop beer can filling machine from Trano Keg Company, breweries can achieve even greater efficiency in their operations. This compact machine offers the same level of performance as larger models but requires less space, reducing overhead costs associated with facility expansion.

Long-term Savings in Labor and Productivity Expenses

By implementing an automatic beer can filling machine, breweries can achieve long-term savings in labor and productivity expenses. With manual filling processes, human error and inconsistencies often lead to product waste and reduced efficiency.

The precision filling capabilities of automatic machines ensure accurate measurements every time, minimizing product waste due to under or overfilling. This not only saves money by reducing material costs but also improves customer satisfaction by delivering consistently filled cans.

Additionally, the user-friendly interface of Trano's automatic beer can filling machines allows for easy operation without extensive training or specialized skills. This eliminates the need for dedicated personnel solely responsible for operating the machine, further reducing labor expenses.

Quick Return on Investment with Streamlined Operations

The implementation of an automatic beer can filling machine offers a quick return on investment for breweries. With increased efficiency and reduced production costs, breweries can recoup their initial investment in a relatively short period.

The customizable settings of Trano's automatic filling machines allow breweries to adapt the machine's performance to meet their specific needs. Whether it is adjusting fill levels or accommodating various can sizes and beverage types, these machines provide flexibility that contributes to an efficient operation.

By embracing automated solutions like Trano's beer can filling machines, breweries position themselves ahead of the competition in the brewing industry. The combination of cost-effectiveness, improved productivity, and customer satisfaction ensures long-term success and growth in this highly competitive market.

Conclusion

In conclusion, embracing the future of beer can filling technology is essential for breweries looking to improve their production processes and stay ahead of the competition in the brewing industry. By choosing Trano as a reliable and efficient machinery provider, breweries can elevate their production with automated solutions that enhance efficiency, reduce labor costs, and ensure consistent filling quality for customer satisfaction.

Trano keg company is a trusted designer and exporter of stainless steel beer kegs, known for their expertise in delivering reliable brewing equipment. With an international reputation for superior customer support and collaboration with breweries to optimize production processes, Trano is the ideal choice for breweries seeking top-quality machinery.

By investing in an automatic beer can filling machine from Trano, breweries can benefit from features such as high-speed filling for increased productivity, precision filling to avoid product waste, a user-friendly interface for easy operation, and customizable settings to meet specific brewery needs.

The benefits of using an automatic beer can filling machine are numerous. Breweries can experience enhanced efficiency and reduced labor costs, minimal downtime, increased production output, and compatibility with various can sizes and beverage types. This not only leads to cost-effectiveness but also ensures a quick return on investment through streamlined operations.

To ensure seamless integration of the automatic beer can filling machine into brewery operations, Trano offers professional installation assistance. Additionally, routine maintenance guidelines are provided to ensure longevity and optimal performance. In case of any machine-related issues or troubleshooting needs, Trano's technical support is readily available for prompt assistance.